Alfa Laval - LKC-2 Non-Return Valves

Product Info

Supplier Info

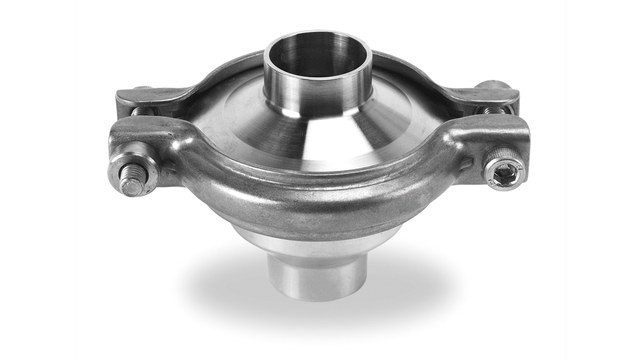

Specially designed for use in stainless steel pipe installations, LKC-2 non-return valves prevent the reverse flow of fluids. Widely used in various processes throughout the sanitary industry, these standard non-return valves are safe and highly reliable.

Related Industries:

Food and beverage, Home and Personal care

SAFE AND RELIABLE PROCESS PROTECTION

Alfa Laval LKC-2 non-return valves are highly reliable check valves ensure single directional product flow through process lines. This provides protection for process equipment that can be affected by reverse flow and prevents pressure surges and/or system shutdown.

NON-RETURN VALVE RANGE

The standard range of Alfa Laval LKC-2 non-return valves are constructed of standard 304 or acid-resistant 316L stainless steel. Easy to install, the valves are designed to handle maximum product pressure up to 10 bar and temperatures ranging from -10°C to 140°C (EPDM). For added versatility, these check valves are available with either a semi-bright or polished finish, and a variety of welding ends for ISO or DIN connections.

Concept

Non-return valve LKC-2 is designed for use in stainless steel pipe

installations to prevent reverse flow.

Working principle

LKC-2 opens when the pressure below the valve plug exceeds the

pressure above the plug and the spring force.

The valve closes when pressure equalization has been achieved. A

higher counter pressure will press the valve plug against the seat.

Standard Design

The valve body is in two parts, assembled by means of a clamp ring

and hygienically sealed with a special seal ring. A guide disc and four

legs guide the spring loaded valve plug with an O-ring seal.

The valve is available with welding ends for tubes according to ISO

and DIN 11850.

TECHNICAL DATA

Temperature

Max. temperature: . . . . . . . . . . . . . 140°C (EPDM)

Min. temperature: . . . . . . . . . . . . . . -10°C

Pressure

Max. product pressure: . . . . . . . . . . 1000 kPa (10 bar)

Mechanical

Required differential pressure for opening the valve when fitted in a

vertical pipe, as shown in fig. 3, is approx. 6 kPa (0.06 bar)

PHYSICAL DATA

Materials

Product wetted steel parts: . . . . . . . . 1.4301 (304) / 1.4404 (316L)

External surface finish . . . . . . . . . . . Semi-bright (blasted)

Internal surface finish . . . . . . . . . . . . Bright (polished), Ra < 0.8 µm

Product wetted seals: . . . . . . . . . . . EPDM rubber

Options

Product wetted seal rings of Nitrile (NBR) or Fluorinated rubber (FPM).

Attachment Link:

Loading...Please Wait.

Loading...Please Wait.